The Red List prevents the use of hazardous substances

“We must take responsibility as a company and make sure that our products do not contain substances that are harmful to the environment or to human health,” she explains.

Chemicals substances are present everywhere. Plastic components, cables, wires, tyres and parts of instrument panels are just some examples of the Volvo Group’s products that contain different types of chemical substances.

EU legislation is largely responsible for determining which chemicals are banned because they have a negative environmental impact or are harmful to human health. However, many countries throughout the world comply with requirements of EU laws and the regulations are becoming increasingly global in nature.

Entire life cycle

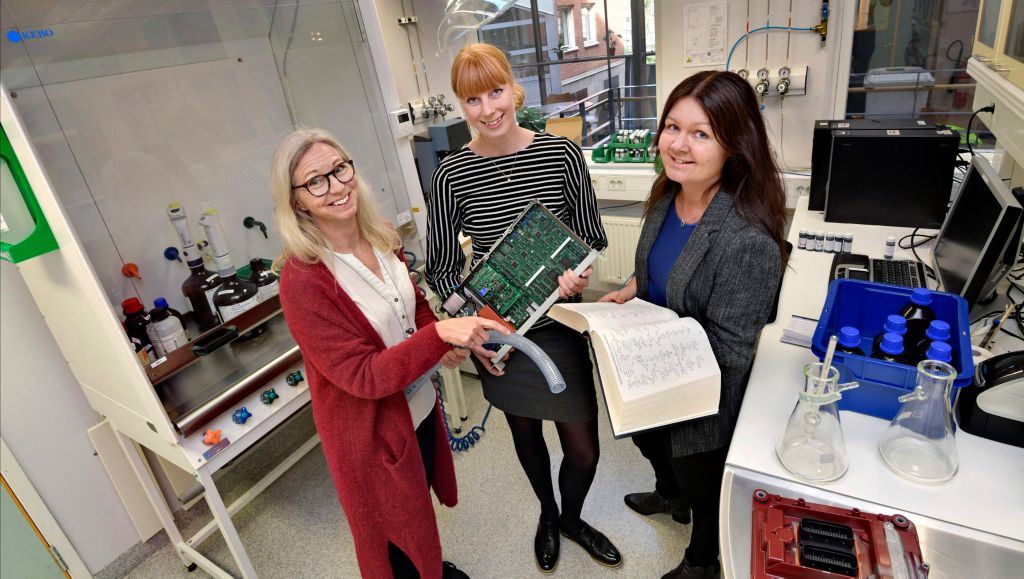

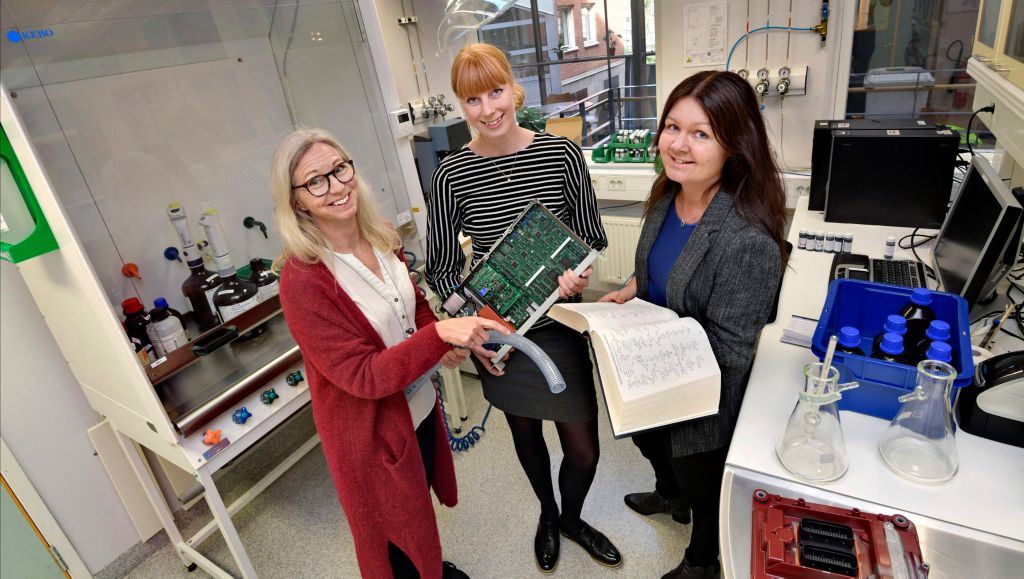

“It goes without saying that it is important for us to do business sustainably in all our markets and to take responsibility for ensuring that our products do not make people ill. We must also keep track of the contents of our products to ensure that the entire product life cycle right through to the recycling phase does not involve hazardous substances,” says Karin Alenius, a regulation specialist on substances of concern at GTT.

Her job is to monitor the legislation and make sure that the group’s Red List is kept updated. She also keeps track of any new regulations.

“We have to stay ahead of the game and be prepared to phase out borderline substances quickly. Preferably this should be done before they are banned completely. This means that we can keep to a minimum the number of unnecessary interruptions to our production and our processes,” she says.

Makes their job easier

The Red List is primarily used by the group’s purchasers, product developers and design engineers. The list makes their job easier when new materials or products are being used.

Anna Sjövall, a standardization engineer at GTT, is responsible for the processes relating to the group’s various standards. She believes that the Red List is a very important tool.

“Instead of searching through the jungle of legislation and regulations themselves, design engineers, for example, can rely on the fact that all the substances which they are not allowed to use are shown on the list,” she explains.

Right from the start

Sofia Lundemo, a business improvement leader at GTP, works with the group’s suppliers. She also sees the advantages of the Red List.

“The list allows suppliers to use the right materials from the start. This means that they do not run the risk of causing delays by having to replace certain substances. They can easily check the contents of their products against the list and find out what they need to know,” she says.

A major update of the Red List has recently been completed. The aim was to extend the list and include certain critical substances that the group needs to keep control over.

“Part of our job is to be proactive. For instance, in the updated version we have added substances which are permitted, but which suppliers must declare if they use them,” says Karin Alenius.

One example of this is the conflict minerals: tin, tantalum, tungsten and gold. The supply chains for these substances often involve major social and environmental problems. Because these minerals are now included on the Red List, it is easier for the Volvo Group to monitor the supply chains. This also highlights the fact that it is important to have control over certain substances.