Next step in the development of natural gas engines

In 2017, Volvo Trucks launched a natural gas-fuelled Volvo FH for heavy regional and long-haul transports. The engine boasts the same performance as a standard diesel-powered truck – but with 20% lower carbon dioxide emissions. In order to further develop the technology, the Volvo Group has now taken part in an EU project aiming to promote technologies that reduce emissions of greenhouse gases, such as carbon dioxide. The project, HDGAS, ran for three years and concerned the development of engines and trucks for liquified natural gas (LNG). Alongside the Volvo Group, the project also involved MAN and Iveco, among others.

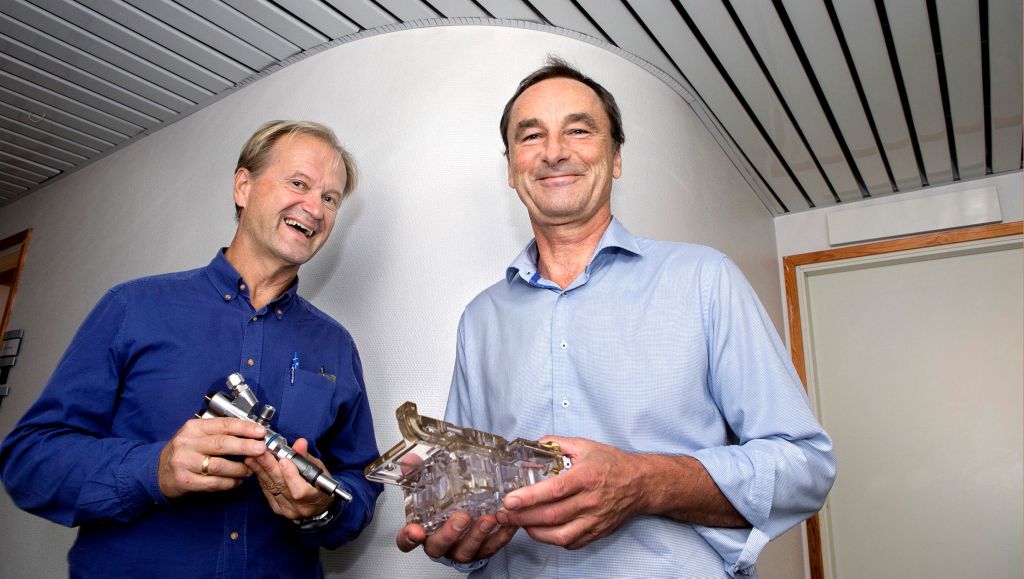

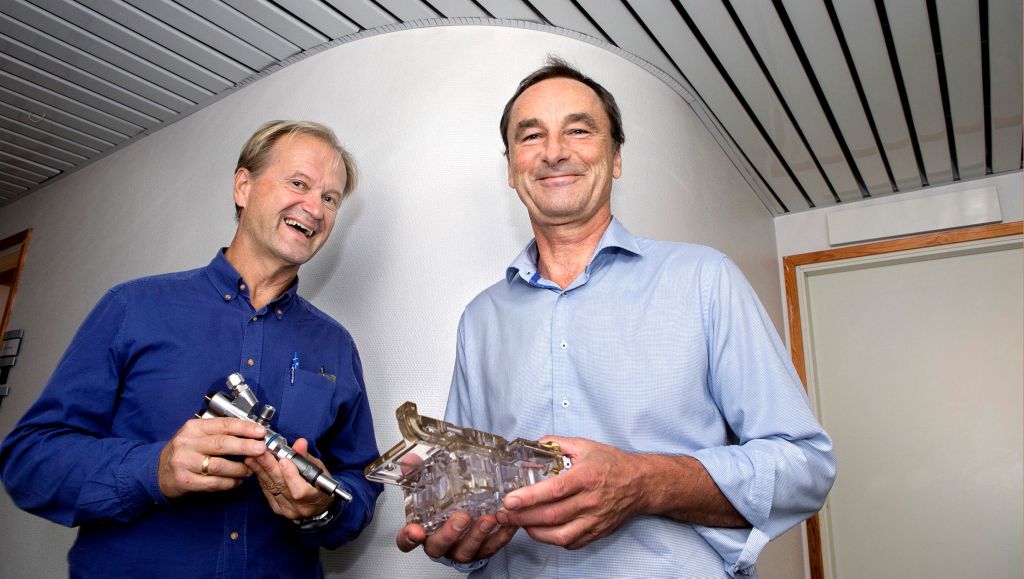

“The project was carried out in close collaboration between the parties, for example in relation to improving the technology and refuelling the truck. We also worked separately and produced our own engine concept together with our own suppliers,” Magnusson reports.

Success for Volvo

The parties recently presented their results to the European Commission, and for the Volvo Group, it was a success.

“Yes, we really succeeded in meeting the high demands set by the Commission. It feels amazing,” Magnusson exclaims.

His colleague Jan Arnell, project manager for technical development, agrees.

“It’s been an exciting and interesting time,” he says. “Now we can take this to the next level.”

The requirements set by the Commission included a 20% reduction in greenhouse gases, the replacement of diesel with over 90% natural gas and the possibility to drive over 800 km on a single tank of fuel.

“We managed it comfortably,” Magnusson reveals. “What’s more, our engine boasts low exhaust emission levels. Particulate emissions, in particular, are much lower than from a diesel engine.”

He goes on to explain that the project experimented with different pressures for the gas fed into the engine and found that higher pressures do not necessarily increase efficiency and are not necessarily needed in order to meet current exhaust gas requirements.

“We did tests at 300 bar and then increased to 500. The big advantage of higher pressure is that the exhaust gas emissions can be reduced further, from already low levels, without affecting the efficiency. That was one of the key things we learned for the future,” Magnusson explains.

Extensive knowledge

One of the reasons that the Volvo Group’s engineers were so successful, according to both Magnusson and Arnell, is the extensive knowledge available within the Group. The natural gas-fuelled engine has been under development for a long time within the Group.

“We already have a commercial product to start from and develop further into the next generation of engine,” Magnusson elucidates.

Another reason for the positive result is our collaboration with the technology providers, Bosch and AVL.

Magnusson and Arnell reveal how the engineers from the Volvo Group met representatives from the technology providers every other week for three years and carried out tests together.

“They really did their homework and demonstrated a great deal of expertise and commitment,” Arnell observes.

The team working on the project within the Volvo Group consisted of around 10 people, but over the course of the project at least 75 persons within the Group were involved.

Magnusson sees natural gas as a good alternative to diesel and believes that it is important for the Volvo Group to evaluate different technologies for the future. Alternative fuels can provide sustainable solutions, not just in a transitional phase but also in the long term, he believes.

“After all, we’ve come a long way if you take the development of electric vehicles as an example, and natural gas is another case where we have the expertise and the opportunity to expand our horizons in multiple areas,” he concludes.

Read more about the project here.

Read more about the natural gas-fuelled Volvo FH.

Read more about how we work with innovation.

Interested to join our teams? Visit our Career page.